Damping series

1.Product composition

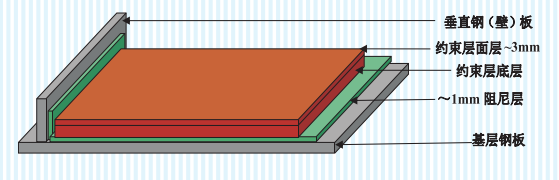

TD08-6 damping coating (smooth flat type) is a composite high performance damping coating with polyether ammonia ester/epoxy resin interpenetrating polymer network as the damping layer and solvent-free epoxy resin curing system as the restraint layer. The damping layer consists of two components, "damping layer Group A" and "damping layer group B". Component A is a light yellow viscous liquid, and component B is a green powder. The constraint layer consists of two parts: the bottom layer and the surface layer. The bottom layer of the constraint layer is composed of "constraint layer component A" and "constraint layer component B". The restraint layer (leveling layer) is composed of three components: "Restraint layer (leveling layer) Component A", "restraint layer (leveling layer) component B" and "restraint layer (leveling layer) component C (powder)". The restraint layer (leveling layer) component A is a viscous liquid packaged in iron drums, and the restraint layer (leveling layer) component B (leveling agent) is a brown-red liquid packaged in plastic bottles. Restraint layer (leveling layer) C component (powder) in plastic bags.

2.Product characteristics

This product has the following features:

1, High Composite loss factor, significant vibration and noise reduction effect;

2, strong adhesion, no cracking, no falling off, long service life, no maintenance;

3, non-toxic, environmental protection, good flame retardant, normal temperature reaction curing, convenient construction;

4, wide damping temperature range (-40℃~160℃), strong environmental adaptability;

5, the surface is smooth and smooth, beautiful and practical, conducive to cleaning and hygiene.

3.Technical index

| Type | Testing item | Unit | 標(biāo)準(zhǔn)值 | |

| Damping layer | time of drying | surface drying | h | ≤6 |

| Actual drying | h | ≤12 | ||

| Adhesion (pulling method) | MPa | ≥1.8 | ||

| adhesion force | grade | 1級以上 | ||

| density | g/cm³ | 1.1±0.1 | ||

| Confining layer | time of drying | surface drying | h | ≤4 |

| Actual drying | h | ≤8 | ||

| Hardness (Shao A) | ≥95 | |||

| density | g/cm3 | 1.5±0.1 | ||

| Post-recombination | Composite loss factor | nc | ≥0.2 | |

| Resistant to 0# diesel | mouth | ≥6,Coating does not rust, does not bubble, does not fall off | ||

| 3% brine resistance | mouth | ≥6,Coating does not rust, does not bubble, does not fall off | ||

| Smoke toxicity | Comply with Part 2 of Annex I to the FTP Rules 2010 | |||

| Surface flammability | Comply with Part 5 of Annex I to the FTP Rules 2010 | |||

| density | g/cm³ | 1.5±0.1 | ||

| appearance | flat and smooth | |||

4.Design thickness

This product has the following features:

1, High Composite loss factor, significant vibration and noise reduction effect;

2, strong adhesion, no cracking, no falling off, long service life, no maintenance;

3, non-toxic, environmental protection, good flame retardant, normal temperature reaction curing, convenient construction;

4, wide damping temperature range (-40℃~160℃), strong environmental adaptability;

5, the surface is smooth and smooth, beautiful and practical, conducive to cleaning and hygiene.

5.Product structure