Damping series

1.Product composition

TD08 damping coating is a composite high performance damping coating with polyether ammonia ester/epoxy resin interpenetrating polymer network as the damping layer and solvent-free epoxy resin curing system as the restraint layer. The damping layer comprises two components, A damping layer group A and a damping layer group B. Component A is a light yellow viscous liquid, packed in a small iron drum of 3kg; B component is green powder, packaged in plastic bag 4.5kg. The confinement layer comprises two components: confinement layer group A and confinement layer group B (curing agent). Among them, component A is iron red (or black) paste, packed in 10kg iron drum, component B (curing agent) is brown-red liquid, packed in 650g plastic bottle.

2.Product characteristics

This product has high composite loss factor, wide damping temperature range (-40℃~160℃), non-toxic, good flame retardant, normal temperature reaction curing, strong adhesion, no cracking, no falling off, convenient construction, suitable for vibration and noise reduction of plane or complex surface parts with substrate thickness greater than 5mm. This product can be painted on a clean substrate or a variety of bottom coatings, has been used on more than 400 domestic ships and a variety of ventilation pipes, soundproof doors and Windows, mechanical equipment, damping vibration and noise reduction effect is remarkable, the test results show that: the vibration attenuation efficiency of the first order vibration mode curve is 94.9%, can reduce noise 8 ~ 20 dB.

3.Technical index

| Type | Testing item | Unit | Standard value | |

| Damping layer | time of drying | surface drying | h | ≤6 |

| Actual drying | h | ≤18 | ||

| Adhesion (pulling method) | MPa | ≥1.8 | ||

| density | g/cm³ | 1.1±0.1 | ||

| Confining layer | time of drying | surface drying | h | ≤4 |

| Actual drying | h | ≤12 | ||

| Hardness (Shao A) | ≥95 | |||

| Flame retardant (oxygen index method) | % | ≥36 | ||

| Density | g/cm³ | 1.5±0.1 | ||

| Post-recombination | Composite loss factor | nc | ≥0.2 | |

| 0# diesel resistance (90 days) | Coating does not rust, does not bubble, does not fall off | |||

| Adhesion of composite coating | Mpa | ≥1.8 | ||

| Smoke toxicity | Meet FTP2010 FTP rules annex I in part 2 | |||

| Surface flammability | Meet Annex I Part 5 of the 2010 FTP Rules | |||

| Density | g/cm³ |

1.5±0.1 |

||

4.Design thickness

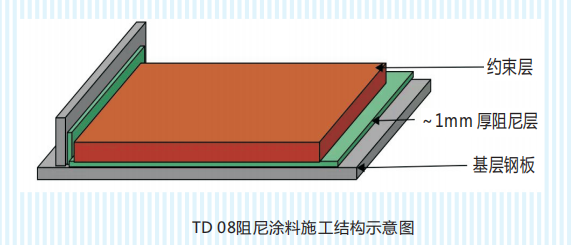

The total thickness of the restraint layer and the damping layer is 1.5 ~ 2 times that of the base steel plate, and the damping layer thickness is ~ 1mm.

5.Product structure